-

Management Of Change (MOC) Work Flow In Oil And Gas

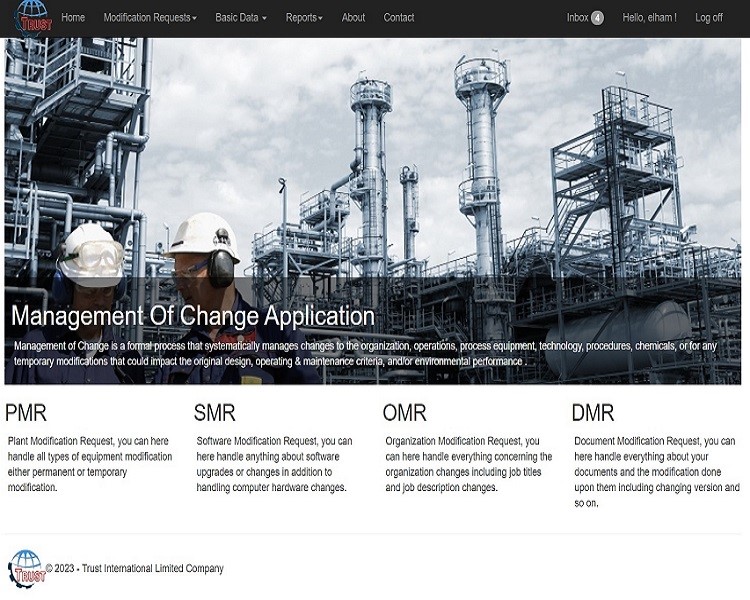

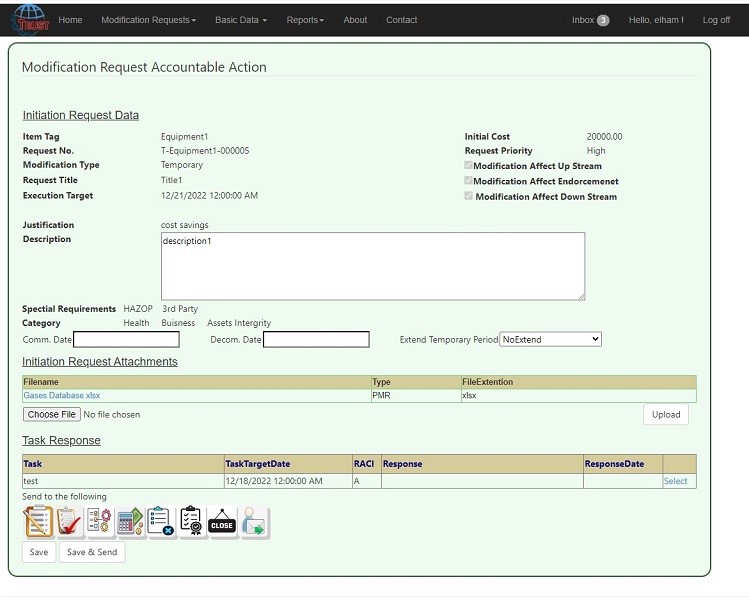

MOC is essential element in many ISO standards such as 9000, 14000, 45000, 55000 etc. to implement MOC as a management systems, an approved procedure must be in place defining the scope of change, permanent/temporary, what are the drivers of the change ( business, HSSEQ, technology, performance enhancement etc.). TIL has developed a software package encompasses the procedures of change from A to Z with closure of updating CMMS, PIDs, operating manuals, specifications etc.

The system is designed to be compatible with the industry’s risk management, quality, and improved performance, organizational structure; software/hardware changes, and company's documentation system

Therefore we have considered the following during the development of MOC software:

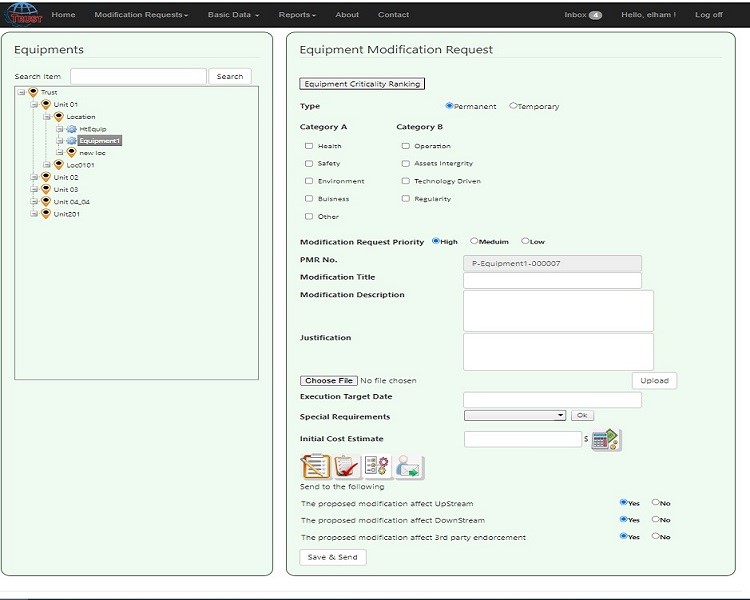

- Define the need for and the proposed change and its impact on HSE, performance, etc.

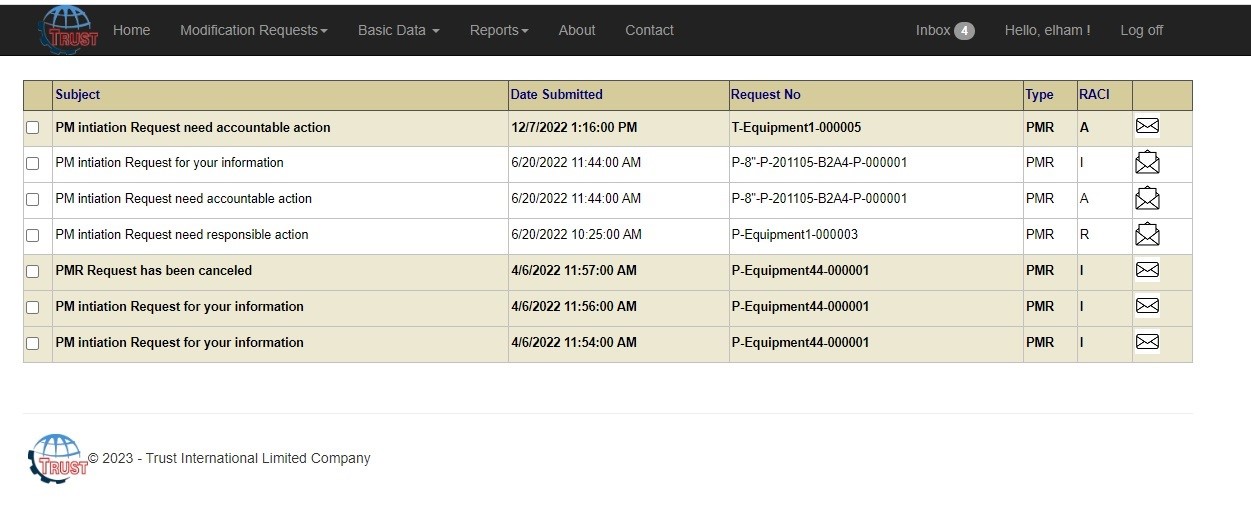

- Establish accountability/responsibility levels (RACI chart).

- Define the criteria that triggers the change demand.

- Define the estimated budget with reasonable tolerances, as well as the payback of the requested change , may be reduced risk or better performance etc.

- Defined the involved officers along with the approval cycles, and their roles and responsibilities, and the deliverable dates within internal interaction correspondences that included the software package, i.e. no need for external email exchanged messages.

- Define the added values of implementing a specific MOC scope encompasses:

- Reduced HSE risks, or better working environment

- Reduced property damage and the subsequent business interruption

- Eliminate the short cuts that may cause potential threats for the employees or business

- Consistent work flow and established procedures to accomplish the change from start to finish

- Register all the changes with archiving system for historical purpose and future references when needed

- ensure that all the changes were reviewed and genuinely have added values

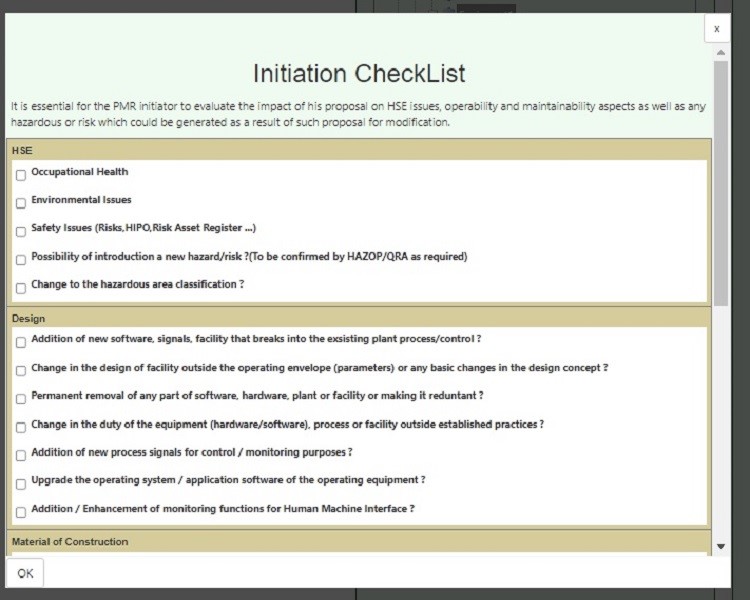

- Establish check lists to control that maintains the purpose of change during the cycle of every progressing change when needed.

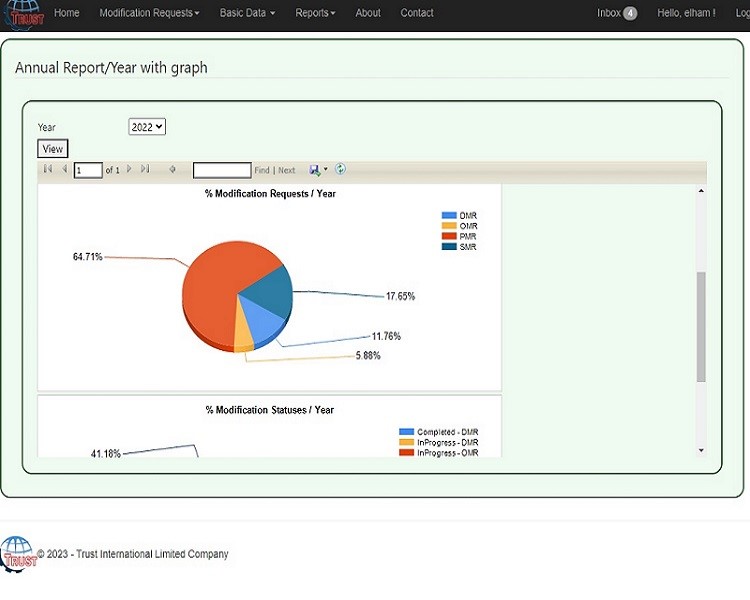

- Establish status report to show what happened for every change request and provide the necessary help to push it as timely planned.

- Provide a predefined course of actions when the temporary modification period is elapsed, i.e demolish, continue for another period of time, or convert into permanent.

- Provide a cancellation process when needed and show the reasons of cancellation.

- Define the engineering work details in a technical package that highlighting detailed scope of work and the delivered quality testing process.

MOC

-

What is MOC

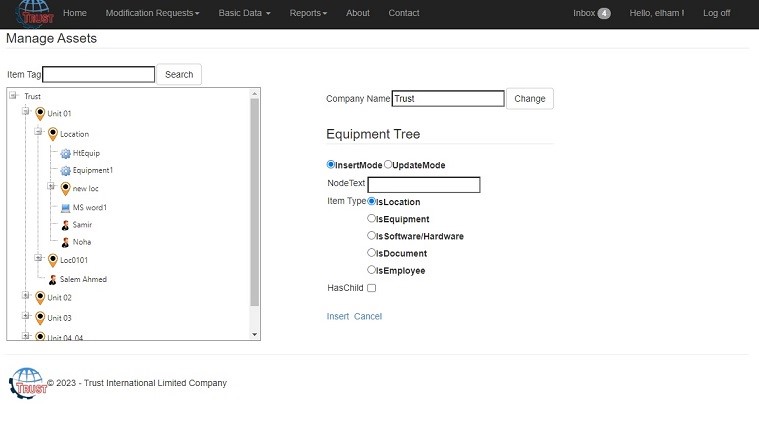

A system designed for the management of changes that can be performed on employees, documentations, software/hardware, and process/utilities equipment.

-

Features

1.It defines the type of change permanent or temporary

2.It Will justify and verify the requirement for changes requirements based on corporate plans.

3.It will determine the preliminary requirements and direct it into technical authority for action.

4.MOC guides preparation of the engineering package with estimated costs and seeks approval of operations authority.

5.Updating all relevant drawings, documentations, training requirements etc.

6.Archiving system for future reference to carry out similar modifications